The Evolution of Maintenance: Part 1 – Embracing Preventive Strategies with OPM Software

Achieving daily production goals can be challenging when machinery malfunctions cause unplanned downtime, missed deadlines, and increased repair costs. With aging equipment as the leading cause of unplanned downtime1 some failures are inevitable. But choosing the right maintenance strategy can significantly reduce their impact and frequency and prolong the life of critical assets.

This is the first in a series of articles examining the relationship between the drivers for increased operational efficiency and more effective plant maintenance. In this first article, we set the stage by exploring two fundamental maintenance strategies – reactive maintenance and traditional preventive maintenance, and how operational performance management (OPM) software continues to be a key player even in these basic maintenance approaches.

In subsequent articles, we will look at newer preventive approaches such as condition-based maintenance and predictive maintenance, and then we will examine how cloud technologies for Machine Learning and Predictive Analytics can be used to further enhance maintenance strategies. We will also look at the costs and benefits of the various strategies and how Ekho OPM can support your operations regardless of where you are on the path to optimization.

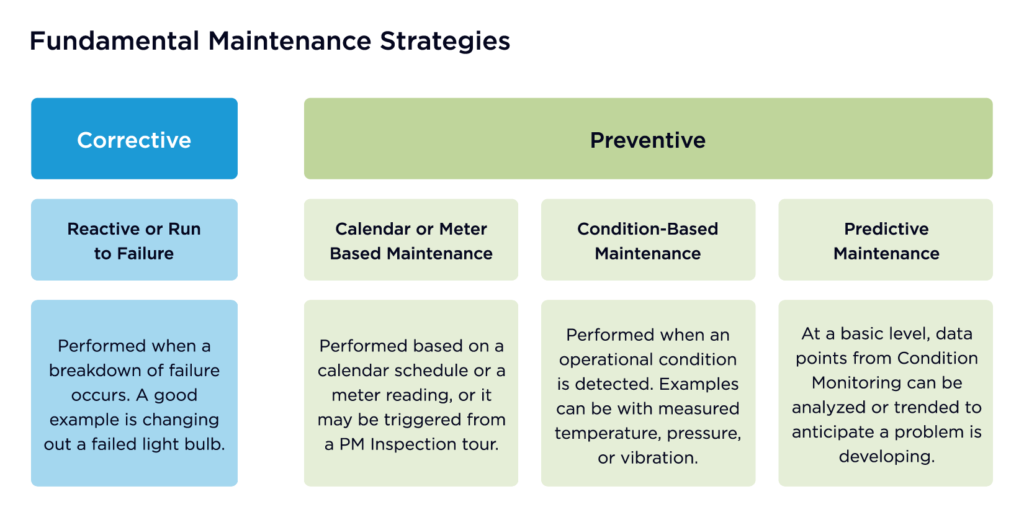

The framework we will be using for these articles is presented below:

Traditionally, corrective or reactive maintenance has been the norm, where repairs are carried out after equipment failure occurs. However, thanks to technological advancements, more advanced strategies are gaining momentum. Those who invest in the technology that facilitates a more proactive approach see longer durations of equipment availability without malfunction, which sets the stage for better performance and higher quality; the three factors used to calculate Overall Equipment Effectiveness (OEE). OEE is a window into efficiency and therefore, should be considered when aiming to improve your operations.

In this initial blog post, we will explore the benefits of basic preventive maintenance over reactive maintenance and how adopting OPM software, such as Ekho OPM, can empower your team to take proactive measures to increase OEE.

Reactive Maintenance:

Reactive maintenance, also known as “breakdown maintenance,” addresses equipment failures after they occur. While this approach can be effective with low-priority equipment with a low cost to replace, if used for critical assets it can disrupt production schedules, lead to higher repair costs, and pose safety risks for workers. Surprisingly, in 2022, more than 92% of manufacturing companies worldwide still employed reactive maintenance on 35% of their assets2.

The good news is that shifting to a preventive maintenance strategy can help mitigate these challenges and boost productivity, improve safety, and keep costs down.

Preventive Maintenance:

Preventive maintenance is a proactive approach that works to prevent potential failures, with the goal of minimizing unplanned downtime and extending equipment lifespan. Regular inspections and planned maintenance practices, like Clean, Inspect & Lubricate (CIL), Time-Based Maintenance (TBM), or Meter-based maintenance (MBM) play a crucial role in this strategy. For example, one common preventive maintenance practice is lubricating certain components every 14 days to reduce wear and improve reliability. These maintenance services are carried out on a pre-determined schedule as part of the maintenance strategy.

Comparison and Contrast:

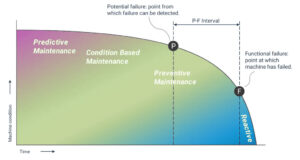

An important contrast between these two strategies lies in how preventive maintenance helps pinpoint defects and identify the cause of potential failures ahead of reactive maintenance, as shown in the P-F Curve diagram below. The P-F curve charts how a machine’s condition declines as time goes on and demonstrates how different maintenance strategies can spot potential failure (P) before actual failure (F). The time between these two points is simply called the P-F interval. The P-F interval allows maintenance teams to better predict when a failure might occur based on the early detection indicators, enabling them to determine the best possible maintenance schedule for that specific asset.

Apart from minimized downtime and increased OEE, preventive maintenance brings several other advantages, such as more reliable equipment, cost savings, improved product quality, regulatory compliance, energy efficiency, and a safer working environment. It also boosts employee morale, showing your employees that you care about their safety and job stability.

The Role of OPM Software in Preventive Maintenance:

The right OPM software is key to a successful basic preventive maintenance strategy. Advanced OPM software solutions like Ekho OPM gather real-time data from various sources in your manufacturing environment, including sensors, machine interfaces, and HMI/SCADA systems. They also automatically track critical reliability KPIs, like Mean Time Between Failure (MTBF) and Mean Time to Repair (MTTR), eliminating manual data entry and streamlining data collection and reporting processes.

This streamlined data overview and automatic KPI tracking enables preventive maintenance planning through:

- Downtime Analysis: Identifying critical downtime events affecting equipment reliability, allowing the maintenance team to prioritize tasks based on significance.

- Trend Analysis: Tracking and analyzing reliability KPIs over extended periods to identify patterns and recurring issues for more informed preventive maintenance planning.

- Spare Parts Optimization: Continuously monitoring and analyzing downtime data to optimize spare parts inventory management and prevent major breakdowns.

- Maintenance Scheduling: Analyzing longer-term data trends to schedule preventive maintenance during periods of lower production demand or equipment idleness.

- Enhancing Preventive Inspection: Evaluating the effectiveness of preventive maintenance procedures by assessing reliability KPIs and adjusting maintenance checklists accordingly.

Summary:

By embracing preventive maintenance, industrial manufacturing companies can reduce unplanned downtime, minimize repair costs, enhance operational efficiency, and improve OEE. And leveraging the power of OPM software like Ekho OPM enables more proactive and data-driven preventive maintenance strategies, resulting in improved equipment reliability, minimized downtime, and optimized production efficiency. With the right maintenance approach and OPM software, your team can achieve higher levels of productivity and success in the manufacturing industry.

Where Are You on Your Journey?

The choice of a maintenance strategy ultimately depends on the availability of technology to support the program. If there are no online sensors, and no plant floor systems to collect real-time data feeds, then a preventive maintenance program in conjunction with a reactive component is a perfectly acceptable approach, and Ekho OPM software can support that combination. With the availability of low-cost sensors and handheld monitors and the increased availability of OT networks in today’s facilities, opportunities are available to move into more advanced maintenance strategies as we will discuss in the next article in this series.

For more information get the product sheet or book a demo.

Ekhosoft provides Operational Performance Management software that empowers teams with the critical insights and real-time visibility they need to uncover performance issues faster and create action plans to drive improvements.

© 2024 Ekhosoft. All rights reserved.