Ekhosoft to provide OPM software solution for all Sanimax plants

MONTREAL, Québec, December 14, 2022 – Sanimax Industries Inc. has selected Ekhosoft to deliver and integrate its leading Ekho Operational Performance Management (OPM) platform in a landmark move which will offer Sanimax’s American and Canadian teams enhanced insight, accurate tracking, and a robust digitalized OPM solution across all plants, supporting the company’s vision for future success.

Sanimax, an established provider of agriculture and animal nutrition products in the agri-food industry, operates manufacturing plants across Canada and the United States reclaiming and transforming organic material into high-quality ingredients for several industries. In recent years, the company identified a growing need to reduce downtime, cut waste, and improve data insight with accurate data reporting, and increase collaboration across teams.

With no existing system in place that met or served those critical needs, Sanimax sought a solution that allowed them to concentrate their operational objectives in a unified platform that was easily and quickly integrated, well-supported, and could be scaled to meet future goals.

Montreal-based Ekhosoft, a Power Factors company, offered its flagship Ekho OPM solution, a unified product for OPM which allows manufacturing team members to share production issues in real-time, drive improvement initiatives, uncover and measure performance losses and reductions, and promote a culture of continuous improvement via enhanced visibility and accurate data portrayals.

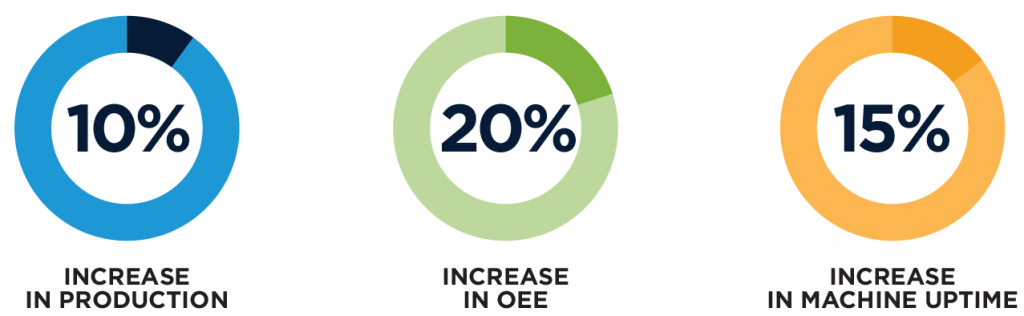

After a three-month proof-of-concept (POC) period which saw the integration of Ekho on a Sanimax production line, it was further integrated across all five Montreal-based production lines after meeting and exceeding the company’s OPM goals. At the conclusion of the POC, Ekho’s adoption and utilization had grown to the point where over 90% of Sanimax’s production line team were conversant with the solution’s user-friendly interface and were able to glean more insight into their processes including in relation to other production lines.

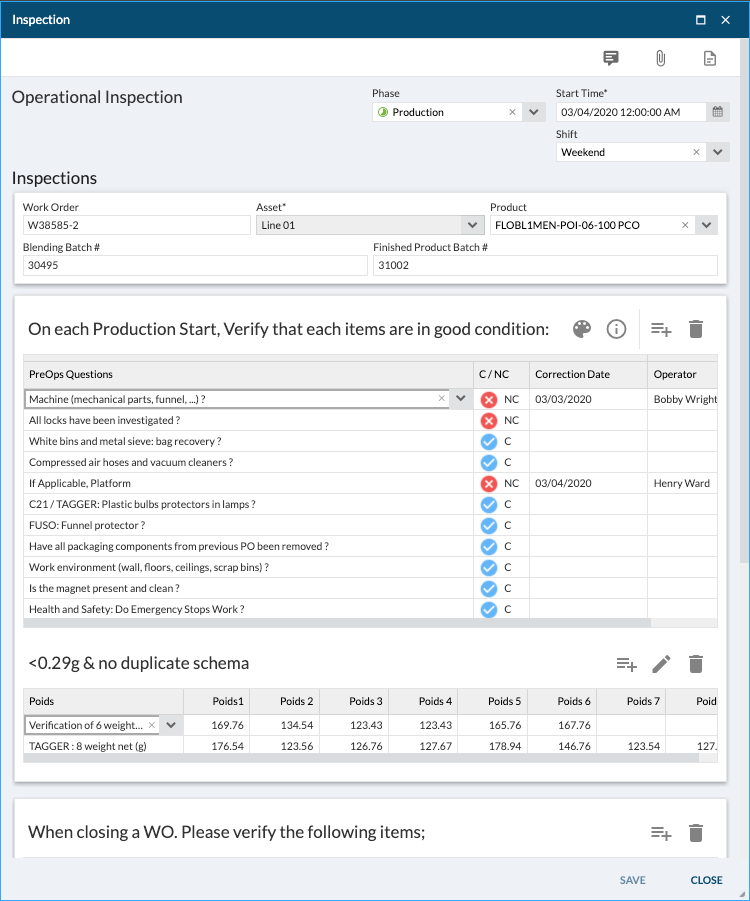

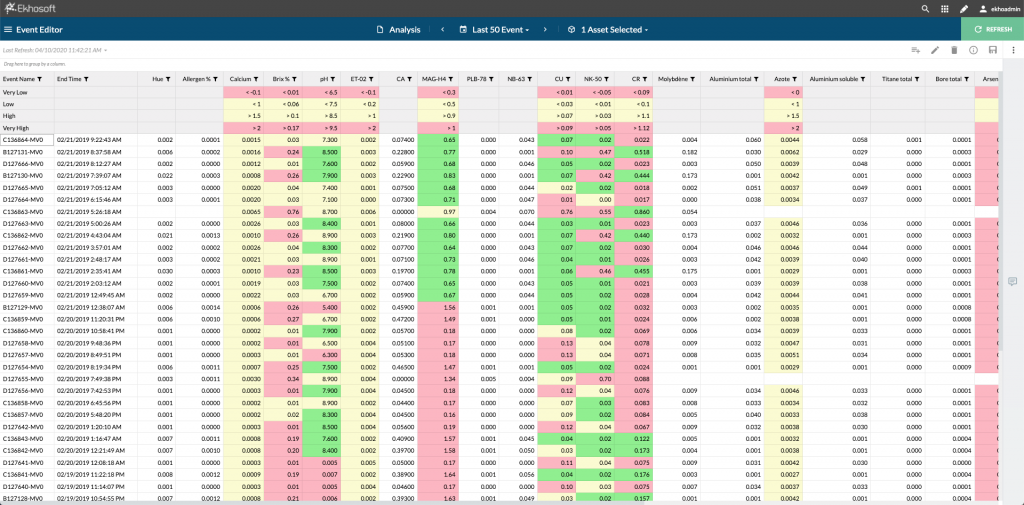

Ekho was selected as the winning all-in-one application solution, offering Sanimax’s team members the ability to simultaneously monitor Key Performance Indicators (KPIs), Overall Equipment Effectiveness (OEE), downtime tracking, production operations, efficiency matching, and more, while offering improved data insight and a better understanding of how to position manufacturing processes while drastically scaling down on waste.

“Sanimax is excited to launch Ekho in its plants,” says Martin Lortie, Manager, Automation and Electrical. “This solution answers the needs we were looking for. With its user-friendly dashboard, we are certain that it will allow our team to be more effective and improve our production.”

Among the many benefits, Ekho offers Sanimax also includes documenting events and logging varying data values on a daily basis, accurate reporting and data aggregation through digital forms, measuring and tracking returns to full operational capacity after shutdowns and planned/unplanned downtime, and more.

“Simply put, we’re delighted that Sanimax chose Ekhosoft to assist with meeting their goals for success,” said Patrick Ramsey, VP, Power Factors. “Our OPM solution empowers their skilled teams of operators to make better decisions and undertake informed courses of actions to improve efficiency and cut waste.”

Sanimax will further completely integrate Ekho across all production lines and plants, in both Canada and the United States in 2023.

About Ekhosoft, a Power Factors Company

Ekhosoft is a forerunner in operational performance management and intelligence software solutions, delivering powerful, configurable, and adaptable event-driven application solutions designed for large-scale operations in process and renewable industries. Ekhosoft’s leading Ekho Operational Performance Management (OPM) software is designed to propel process manufacturing plants to peak performance by helping eliminate paper, optimize operations, and drive continuous improvement.

Ekho tracks and builds a real-time picture of overall production through performance, OEE, and KPI dashboards, tightening your control over downtime, rate loss, and quality.

Actively used by numerous customers throughout North and South America, and Europe, Ekhosoft’s innovative solutions drill down into operations to uncover patterns delivering key insights into operations while driving performance and efficiency improvements. With personnel and partners across the world, Ekhosoft is uniquely positioned to serve its customers’ needs on a global scale.

Learn more at ekhosoft.com

About Power Factors

Power Factors develops software to accelerate the global energy transition by empowering all renewable energy stakeholders to collaborate, automate critical workflows, and make the best decisions. Power Factors fights climate change with code.

Power Factors has incorporated its four flagship solutions Drive, Greenbyte, BluePoint, and Unity to build an integrated suite of open and smart apps. These apps are purpose-built for asset management, field service optimization, and performance optimization. Leveraging domain expertise and machine learning-based advanced analytics within these apps, customers can maximize the value of their renewable assets to stay competitive.

Power Factors’ renewable energy software platform is one of the most extensive and widely deployed solutions in the market with nearly 207 GW of wind, solar, hydro, and energy storage assets managed worldwide.

Learn more at powerfactors.com

Media Contact (press only):

Stephanie Hanawalt, Sr. Manager, Marketing, Power Factors

[email protected]